Feed raw materials naturally lose or gain moisture depending on the environmental conditions to which they are exposed, a property known as equilibrium moisture content (EMC). Both EMC and feed milling processes influence the overall moisture level of animal feed.

Moisture, whether naturally present or added during processing, plays a vital role in feed formulation. Insufficient moisture in mash feed leads to increased steam and energy requirements during pelleting, slower throughput, reduced starch gelatinisation, and consequently, lower pellet durability.

However, it is crucial that moisture within the feed is properly bound. The presence of free (unbound) water raises water activity, increasing the risk of microbial growth and product spoilage.

By incorporating glycerol esters of propionic acid and surfactants, feed producers can enhance water binding and distribution within the feed matrix, optimising pelleting efficiency while maintaining product safety and quality.

Solutions for moisture management

Historically, moisture management technology in feed production was relatively simple. Typical products combined surfactants and organic acids. The surfactant served to reduce water surface tension, allowing water droplets to spread more evenly across the feed and increase contact with feed particles. Meanwhile, propionic acid functioned as an inhibitor of moulds and yeasts, preserving feed quality.

Devenish Nutrition Limited advanced this concept by developing applications for propionic acid esterified to glycerol, resulting in a new generation of moisture management technology known as SmartMoisture.

This innovation introduced the use of esters of organic acids in place of ammonia-buffered organic acids. The covalent bond between propionic acid and glycerol forms a structure that is more stable and less corrosive than the salts of propionic acid. As a result, these products retain propionic acid for longer periods within feedstuffs, enhancing mould inhibition and overall stability.

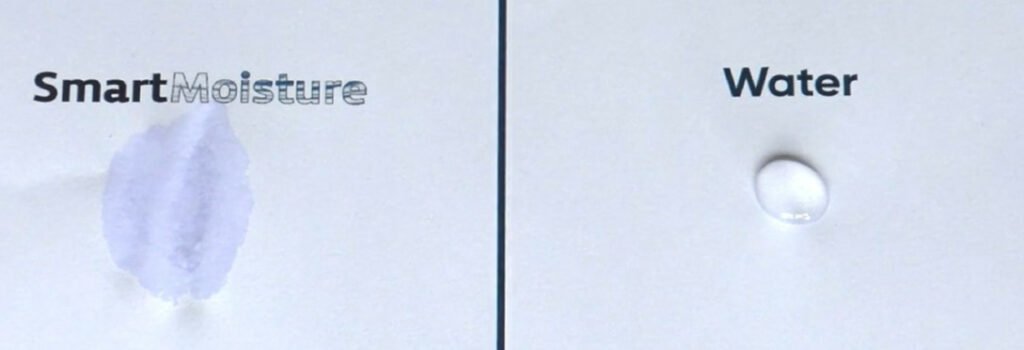

Beyond their preservative effect, glycerol esters of propionic acid are both chemically stable and highly hygroscopic. Their strong humectant properties work synergistically with surfactants: the surfactant reduces water tension, improving moisture distribution, while the humectant attracts and binds water along with propionic acid into the nearest absorbent material, namely, the feed itself.

Water activity is a key indicator of how effectively moisture is absorbed and how much capacity remains for further moisture uptake. A reduction in water activity signifies that added moisture has been successfully bound within the feed, thereby reducing microbial risk.

In evaluating a moisture management program, water activity results provide critical insight into product performance. The combination of glycerol esters of propionic acid and surfactants has demonstrated a clear capacity to lower water activity in treated feed.

In Figure 1, the striped bars represent control samples, while the solid bars indicate feeds treated with 1%, 2%, and 3% SmartMoisture/water solutions. The data show that although overall moisture levels increased with SmartMoisture addition, water activity decreased, confirming the product’s effectiveness in binding moisture and improving feed stability.

Figure 1 – Water activity in finished feed. Reducing water activity in finished feed. Striped bars = control, solid bars = SmartMoisture

Improving starch gelatinisation with SmartMoisture

Devenish’s reputation is founded on delivering innovative nutritional solutions that support feed efficiency and animal performance. In maintaining this standard, it is essential that any additional moisture introduced into feed does not compromise its nutritional value.

With this objective in mind, Devenish has focused on enhancing starch gelatinisation – a key factor influencing feed digestibility and nutritional utilisation – particularly in compound and extruded feeds.

In a recent trial, the effect of SmartMoisture on starch gelatinisation was evaluated by comparing 2 treatments: a control feed with 1% added moisture and a SmartMoisture-treated feed with 1% SmartMoisture added. The feed used in the trial contained 47% starch.

Starch gelatinisation was quantified using a Differential Scanning Calorimeter (DSC). As illustrated in Figure 2, the inclusion of SmartMoisture resulted in measurable improvements in both the percentage of gelatinised starch and the rate of starch gelatinisation.

These findings demonstrate that SmartMoisture not only aids moisture retention but also enhances the physical and nutritional quality of feed through improved starch transformation during processing.

Figure 2 – Gelatinised starch (%) in finished feed (left) and gelatinisation rate of starch (right)

In improving starch gelatinisation, we are able to:

- Improve pellet quality (PDI)

- Reduce fines/dustiness of feed

- Increase glucose absorption in the small intestine

Maximising energy savings and increasing throughput

The inclusion of glycerol esters of propionic acid and surfactants has consistently demonstrated benefits in reducing energy consumption and increasing production throughput, as illustrated in Figure 3 and Figure 4 below.

By optimising moisture distribution and feed conditioning, SmartMoisture enables more efficient pelleting and reduced mechanical resistance within the press. As a result, operational costs are lowered, and the overall profitability of feed mills implementing SmartMoisture is improved.

Figure 3 – Energy savings potential of SmartMoisture. Striped bars represent trials against a positive control.

Figure 4 – Increasing throughput with SmartMoisture. Striped bars represent trials against a positive control.

Service level approach

Supplying a moisture management solution is not a simple drop-and-go process. To achieve maximum benefit, the product must be supported by technical expertise and on-site optimisation. A range of factors – such as conditioning, pelleting, and cooling settings – must be carefully assessed and adjusted to ensure optimal milling efficiency and consistent product quality.

At Devenish, we provide dedicated feed milling support through our team of specialists located across the globe, ensuring that every implementation of SmartMoisture is fully optimised for each mill’s unique setup and production conditions.

Conclusion

Moisture management has become an essential component of a modern feed mill strategy, enabling cost reduction through better control of moisture losses while supporting more sustainable and efficient operations.

Our results to date demonstrate that significant improvements can be achieved across multiple performance parameters, with ongoing research continuing to deliver further efficiency gains and feed quality benefits.