Moisture is often underestimated in animal feed and pet food manufacturing. It is not simply about water percentage; it is about control, consistency, and the balance of processing parameters. Moisture influences nutrient stability, safety, texture, shelf life, quality, and ultimately profitability. Managing it effectively has always been a cornerstone of successful manufacturing.

What has changed is the technology and tools which now available. Once manufacturers relied on other drying methods and routine sampling, while today’s processes can employ real-time sensor systems, predictive analytics, and advanced functional additives to manage moisture more precisely than ever before.

Why moisture management matters

Moisture content plays a central role in 4 key areas of animal feed and pet food manufacturing:

- Nutritional value: Water activity and moisture influence nutrient stability particularly vitamins, fats and proteins.

- Product safety: Excess moisture is the single biggest risk factor for microbial growth.

- Physical quality: Texture, palatability, kibble density, and pellet durability all rely on consistent moisture.

- Economic value: Water is one the cheapest inputs; however, unstable moisture reduces yield and shelf life, causing process inefficiencies, financial losses and product recalls.

In short, poor moisture control affects every link in the value chain, from compliance to consumer satisfaction.

Traditional moisture challenges in manufacturing

- Ingredient variability: Raw materials arrive with fluctuating moisture contents.

- Processing dynamics: Both pelleting and extrusion, including drying and cooling, are highly sensitive to small deviations.

- Environmental factors: Ambient humidity impacts processing, cooling, storage, and packaging.

- Distribution risks: Packaging, and storage that fails to block moisture uptake, can reduce product shelf life and product quality.

Historically, manufacturers responded to these challenges with after the fact testing. But by the time laboratory sample showed deviation, hundreds of kilogrammes of product might already be at risk.

Next-generation moisture sensing

Microwave resonance sensors – Microwave technology has become the backbone of real-time moisture monitoring in bulk solids and agri-food processing. By measuring the dielectric properties of water molecules, microwave sensors can track moisture continuously and non-invasively, even in complex production environments.

Industry research highlights that microwave and NIR technologies are not competitors but complementary tools. Microwave excels in bulk and continuous flow measurement, while NIR provides multi-parameter analysis (protein, fat, moisture) in secondary detail. Using both strategically provides the most comprehensive quality control system.

Multi-frequency and hybrid systems – Recent advances have introduced multi-frequency microwave resonance sensors, which correct for particle size and density variation, significantly improving accuracy and animal feed and pet food environments. Hybrid approaches that integrate microwave with infrared or optical measurement are also emerging, creating multi-layered monitoring solutions.

Hydronix UK has extended its product range specifically for feed, pet food, and related industries:

- Hydro-Mix XT-EX and Hydro-Mix HT-EX are designed for explosive dust environments, the sensors are ATEX, IECEx, and NEC/CSA certified for hazardous locations (dust). This is a significant step for plants processing fine pallets or working under strict safety regulations.

- Hydro-Mix XT-FS has been specifically engineered for food-safe environments. This sensor complies with EN 1935/2004 requirements, making it suitable for pet food facilities where hygiene and regulatory compliance are paramount.

These innovations address not only accuracy and reliability, but also safety and compliance, being two key areas of concern for global feed and pet food manufacturers.

IoT and data-driven integration

Modern sensors are no longer operating isolation. With IoT-enabled connectivity, moisture readings can be integrated into process-wide dashboards. Manufacturers can now track moisture trends across multiple production lines or facilities, applying predictive analytics to anticipate risks.

AI-driven systems further enhance this by learning from historical data:

- Adjusting processing parameters and Machine settings when we are all material batches are detected.

- Predicting microbial risks based on data collected from sensors, and water activity data.

- Optimising processes, and energy usage relating to sensor driven data.

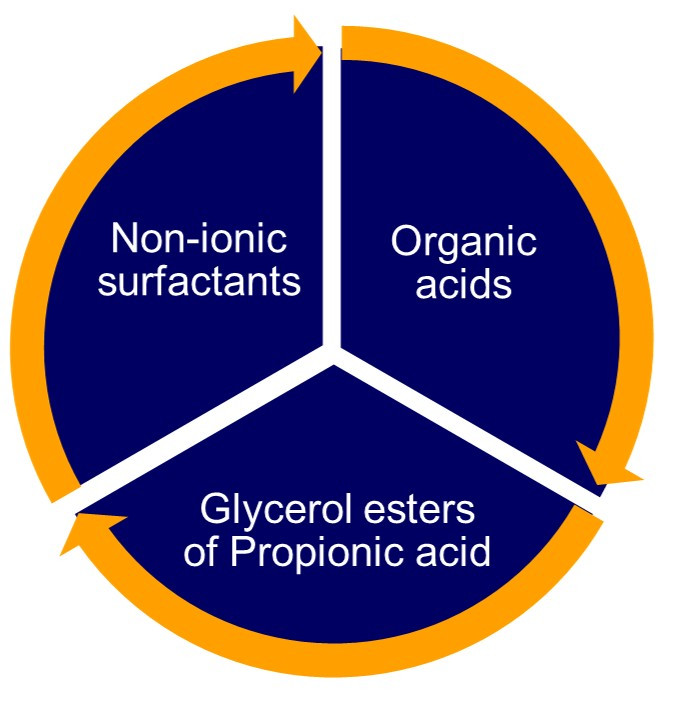

Esterified optimisation products: a parallel innovation

Alongside advances in monitoring, formulation tools are also evolving. Esterified products, molecules derived from organic acids and glycerol’s are being used to stabilise moisture, extend shelf life, and optimising processes.

Benefits and mechanisms

Moisture stabilisation: By binding free water, esterified compounds reduce water activity without compromising palatability.

Moisture stabilisation: By binding free water, esterified compounds reduce water activity without compromising palatability.

Dual functionality: Esterified organic acids, glycerides, and other compounds assist with steam acceptance, for improved steam conditioning and starch gelatinization.

Energy efficiency: By stabilising moisture internally, they can assist with improving pelleting and extrusion efficiencies, and reduce drying requirements, lowering process energy consumption.

Application in pet food and livestock feed

- In extruded pet foods, esterified organic acids help achieve the crunch and aroma pets preferred whilst keeping microbial risks in check.

- In livestock feeds, these esterified products help prevent spoilage in bulk storage silos, particularly in warm and humid climates.

- In both sectors, is esterified products on recently valued as “clean label” alternatives to synthetic preservatives

Combining sensors and functional additives

The strongest approach now combines real-time monitoring formulation-based stability:

Sensors: microwave NIR, and hybrid systems deliver continuous feedback an automated process control.

Esterified additives: Provide product-level moisture stability and protection against microbial risks.

Together, these tools deliver the consistency, efficiency, and reliability needed to satisfy both regulatory agencies and demanding customers.

Regulatory and market drivers

Regulators set strict thresholds for moisture in dry feeds (typically 8-10% in pet foods, and 12-14% in livestock feeds), while consumers, especially pet owners expect freshness, crunch, and nutritional excellence. New explosion safe sensors, and food-grade sensor designs show how manufacturers are responding to both compliance frameworks and consumer-driven standards.

At the same time, sustainability goals are pushing the industry to reduce food waste, optimise energy use, and extend shelf life, all of which are directly impacted by better moisture management.

Looking ahead

The next decade will see continued convergence:

- Sensor innovation: more advanced microwave/NIR hybrid platforms with predictive AI.

- Functional chemistry: broader adoption of esterified additives for clean-label moisture control and stability.

- Smart factories: Fully automated systems where senses and additives work hand-in-hand anticipating variability and optimising processors effectively.

In the future, moisture control won’t just be a quality function, it will be a strategic driver of efficiency, product quality, safety, and consumer trust.

Conclusion

Moisture management is evolving rapidly. With advances in microwave resonance sensors, NIR spectroscopy, IoT integration, and esterified optimisation feed additives, manufacturers now have unprecedented control over one of the most critical parameters in animal feed and pet food production.

These innovations address both process efficiency and product stability, while meeting regulatory requirements and consumer expectations. In an industry where quality, safety, and trust are paramount, mastering moisture management is no longer about reacting to problems it is about proactively engineering consistency, safety, and profitability into every batch.