For OCP Group, sustainability is not a constraint but the compass steering our sourcing, formulation, and delivery of feed phosphate solutions.

To reconcile productivity with environmental responsibility, we build on 3 pillars: high and consistent digestibility; responsible, traceable sourcing; and very low concentrations of undesirable trace elements – heavy metals, which are non-nutritive contaminants that can harm animal health and the environment.

Real digestibility: from performance to measurable sustainability

Sustainability in animal production is now a quantifiable target embedded in formulation decisions. For phosphorus and calcium – critical for growth, bone development, and metabolism – the goal is to meet biological needs precisely, avoiding both under-supply (performance loss) and over-supply (waste and emissions).

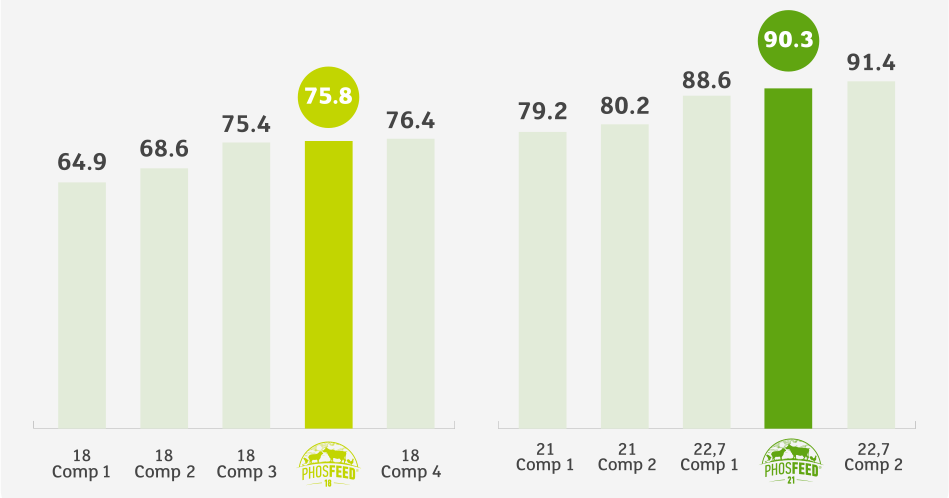

- Proven coefficients. At Wageningen Livestock Research, Phosfeed PureEarth 21 reached 90.3% pre-caecal phosphorous digestibility in broilers, comparable to higher-grade Monocalcium Phosphates, and Phosfeed PureEarth 18 achieved 75.8% standardised total tract digestibility of phosphorous in growing pigs.

- Measurement that matters. In poultry, the WPSA pre-caecal method (indigestible marker + ileal digesta sampling) quantifies true absorption before the large intestine. In pigs, standardised total tract digestibility accounts for endogenous phosphorous losses across the tract.

- From lab to ration. Integrating these in vivo coefficients in formulation software lets nutritionists fine-tune ingredient contributions and the calcium:phosphorous ratio by species and phase – improving biological efficiency, reducing feed costs, and minimising phosphorous excretion.

Unlike in-vitro solubility, in vivo assays capture physiological uptake, enabling a shift from approximation to precision nutrition – the right mineral, in the right amount, no more, no less.

Phosfeed PureEarth 18 & 21 by OCP reached 75.8% and 90.3% digestibility rate, respectively.

Strictly controlled chemical composition

A strictly controlled chemical composition, characterised by extremely low levels of undesirable trace elements, ensures greater safety for animal health and the environment.

This control over composition reduces the risk of accumulation in tissues and effluents, minimises antagonistic interactions between minerals, and ensures compliance with international feed safety and environmental standards.

Thus, the combination of experimentally demonstrated high digestibility and strictly controlled chemical composition represents a cornerstone of precise, sustainable, and responsible mineral nutrition – translating sustainability into measurable, traceable, and reproducible outcomes.

Together, digestibility and controlled chemical composition turn sustainability from aspiration into standard practice – quantified, traceable, reproducible.

Sourcing that sustains – efficient, traceable, low carbon

Sustainable impact begins at the origin. OCP ensures traceable, efficient, and low-emission phosphate sourcing, integrating renewable energy, circular water use, and carbon-smart industrial processes to safeguard continuity, purity, and environmental integrity upstream.

- Energy and emissions – across our sites, 75% of electricity consumed is recovered through cogeneration, avoiding ~20% of greenhouse-gas emissions.

- Water circularity – 100% of process water used on our lines comes from non-conventional sources, enabled by seawater desalination and advanced wastewater treatment.

- Traceability by design – robust quality systems and digital traceability underpin consistent specifications and reliable supply.

This integrated model redefines sustainability as a built-in feature, embedded in formulation, sourcing, and production. It allows nutritionists and producers to meet regulatory expectations while improving feed efficiency and lowering costs.